|

about ael asia electronics technology is a wet process equipment company in the semiconductor wafer manufacturing industry, which focuses on wafer front-end wet etching and cleaning technology. we are one of the leading companies to promote the localization of semiconductor advanced equipment in china. we have set up r&d centers in wuxi, jiangsu, and overseas.

as a high-tech enterprise with independent intellectual property rights, we have applied invention patents for the core technologies and our core products including 8"and 12" bench/single wet etching cleaning tool. we are committed to providing customers with more competitive products and services through diversified and personalized solutions.

to better serve our customer, we have service teams in china major cities. |

product-centic: concentration , quality , cost , perfection , fast

customer first: quick response, problem solving, customer oriented, and win customer trust

teamwork: be practical and realistic , integrity , dedication, mutual respect and trust

delivery mission: fighting , never give up , and fast execution

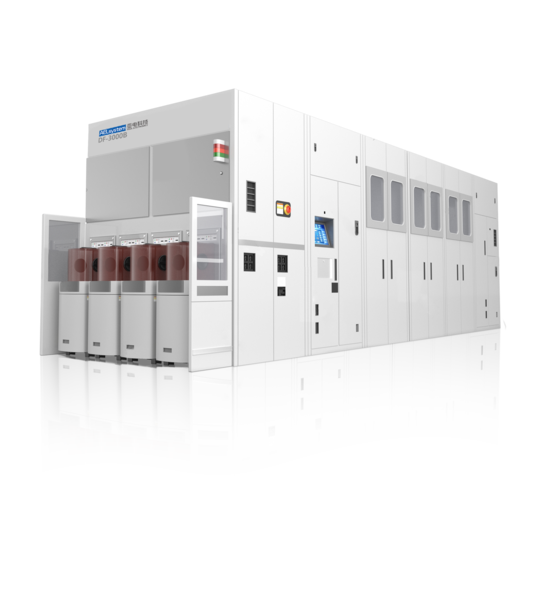

model: | df-3000b |

| type: | cassette less/type |

| wafer size: | 300mm |

| configuration: | 8~12 slots, 2~6 robots (customizable) |

| capable of loading advanced ultrasound and megasonic | |

| slot over-temperature protection, leakage sensor in each module | |

| multiple levels of wafer protection measures | |

| ccss or lcss chemical supply | |

| auto acid replacement, auto liquid filling, liquid dispensing (compatible with various concentrations) | |

| advanced marangoni drying | |

| heating control, concentration control, flow control, pressure control | |

| chemical/water, direct discharge & recycle | |

| reliability: | uptime≥98%, breakage≤1/100000 |

| mtbf≥650 hours, mttr≤3 hours | |

| software: | pc plc gui control, support schedule, eap, fdc and other functions |

model: | fy-3000s |

wafer size: | 300mm |

chamber: | 4~24 chambers (customizable) |

vacuum or grip method | |

4~5 dispenser, 2~3 types of chemicals | |

exhaust separation: acid, alkali, organic chemicals separated | |

efem: | 2 or 4 smif/foup, 1 index robot, 1 or 2 wtr |

chemical supply: | support ccss/lcss supply |

chemical pump circulation | |

heating control, concentration control, flow control, pressure control | |

chemical solution/water, direct discharge & recovery | |

configuration: | ionizer / o3 / hd camera |

reliability: | uptime≥98% breakage≤1/100000 |

mtbf≥500 hours mttr≤3 hours | |

software: | pc plc gui control, support eap, fdc and other functions |